Interlocking Cross Laminated Timber

Interlocking Cross Laminated Timber

RESEARCH TEAM

Jacob GineS

Van Lewis

Jared Barnett

Steve Shrader

Associate Principal, Method Studio

Project Manager, Method Studio

Designer, Method Studio

Business Development, Euclid Timber Frames

SUMMARY OF RESEARCH

Interlocking Cross Laminated Timber (ICLT) is a prefabricated cross-laminated solid-wood wall and roof panel developed by Euclid Timber, LLC in Heber City, Utah. Like Cross Laminated Timber, ICLT is fabricated from 2-7 layers of alternating direction 3” x 6” to 3” x 8” pine stock milled from unwanted wood – primarily locally sourced beetle-killed log pole pine. However, unlike other solid wood panel systems, ICLT utilizes no mechanical fasteners and no adhesives. Instead, ICLTs employ dovetail joining in interlocking and cross-laminate. While the current International Building Code (IBC) does allow for the use of CLT, ICLT panels have yet to be adopted, pending further performance and ASTM testing. Recently, the Department of Civil & Environmental Engineering at Brigham Young University conducted preliminary racking, flexural and axial testing on ICLT panels and ongoing efforts to secure funding for thermal performance, air and vapor permeability, flammability, and acoustic testing.

ICLTs have been used in a few small projects in Utah, including seasonal cabins for the Girl Scouts, a public restroom in San Juan County, a barn and casita in Sevier County, and residences near Sundance and Wasatch County. These projects were built in rural areas that required minimal regulatory oversight. The Utah State University Botanical Center, designed by Method Studio, will be the first state building to be built with ICLT and the first to go through a complete code review. For this project, Method Studio is taking a conservative approach to designing with ICLT by utilizing steel strapping to assure structural strength, applying a sheet vapor barrier behind exterior insulation, and installing a vented steel rainscreen for the exterior cladding system.

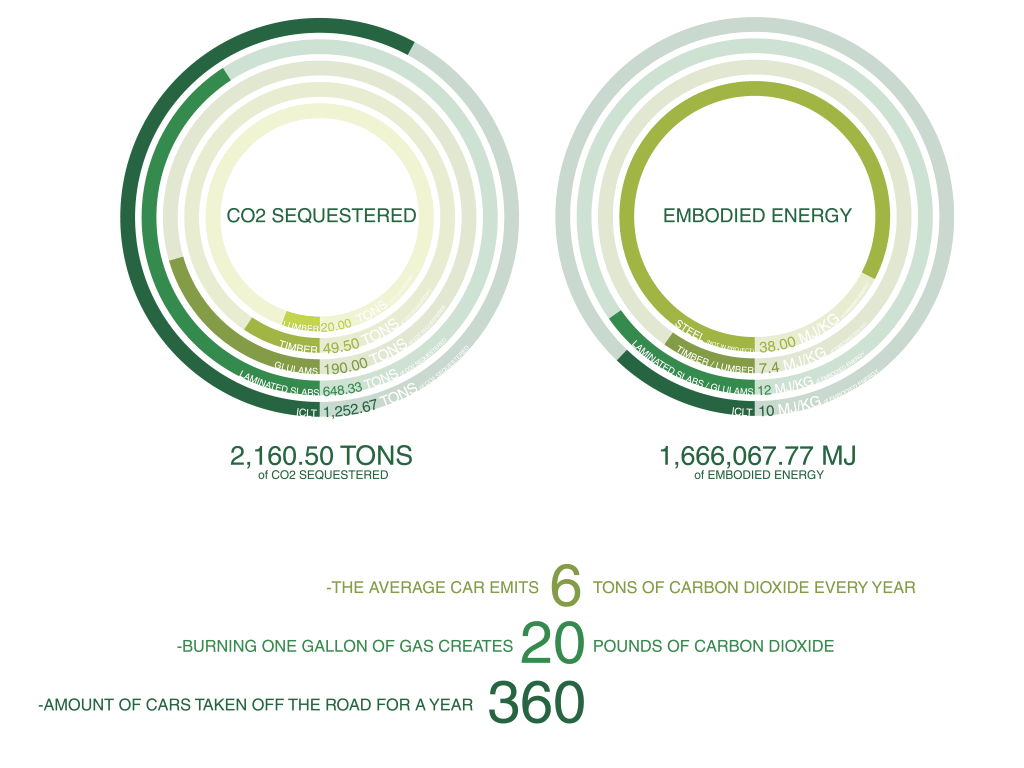

ICLT is an innovative product in its early stages of development. We expect that the full battery of performance tests will reveal that ICLTs are strong, insulative, airtight, and fire-resistant so that we can use them more freely. We do know that ICLTs can benefit the local economy, sequester carbon, and be an important part of western forest management. For now, it’s exciting to be part of bringing a smart new product to market and to work with a team of innovators.

According to recent timber inventories, the United States is home to 751 million acres of forested land, two-thirds of which are designated as timberland. Contained within this inventory are 155 National Forests which include nearly 190 million acres of trees. The vast majority of timberlands in the U.S. (62%) are family/ individual owned and managed. The remaining forest lands are owned by corporations, conservation organizations, clubs, Native American tribes, and others. Around 20% or 150 million acres currently receive third-party certification from either Sustainable Forestry Initiative (SFI Inc.), Forestry Stewardship Council (FSC), or American Tree Farm System (ATFS). These certifications aim to provide responsible and sustainable management of America’s timberlands throughout their life cycle and chain of custody.

Wood is the most significant building material we use today that is grown by the sun. When harvested responsibly, wood is arguably one of the best tools architects and engineers have for reducing greenhouse gas emissions and storing carbon in our buildings.

As our research in wood timber construction continues, we are actively engaged in designing multiple wood timber buildings throughout the region.